EBD Crude Oil and Gas Wells Products

Proprietary Composition Organic Minerals.

ONSHORE AND OFFSHORE OIL WELLS

Boost Oil Production and Reduce Costs

Reduction in scale and sludge build up in oil tubes

Reduction in iron eating bacteria colonies

Increases oil production

Sustainable Solutions To Increase Oil Production and Decrease Expenses

Additional Features

Reduced Power Consumption

Reduction in electric power consumption to run the motor pumps given less friction and lower viscosity.

Remediates Organic and Inorganic Pollutants

Remediates organic and inorganic pollutants including chemicals and heavy metals and greatly benefits the environment

Reduces Emulsification

Reduces emulsification caused by asphaltene in crude oil.

Reduces Maintenance

Reduction in required maintenance and waste water treatment expenditure with prolonged tube and oil rig equipment service life

EBD TECHNICAL SUMMARY FOR ONSHORE & OFFSHORE OIL WELLS

All matter on Earth contains positive and negative energy particles. Environments containing man-made chemicals and pollution such as in oil wells, contain excessive levels of negative energy particles (NEP-) and lack sufficient levels of PEP+. Excessive NEP- volumes increase oil viscosity, piping drag, iron eating bacteria colony concentrations, sludge & wax build up and are also detrimental to living organisms such as microbes. EBD units attract positive energy particles (PEP+) which are naturally present in the ecosystem. By creating an energy particle balance between NEP and PEP+ levels, all atomic frequencies of all matter situated above, below and around the EBD perimeter surrounding the oil well facility, are naturally optimized causing all natural and indigenous microorganisms present within the EBD balanced perimeter to become much more active and much more prolific.

By naturally optimizing: A) atomic excited states and frequencies in matter, B) microbial life in nature and C) physical properties of various natural elements in oil well facilities such as, but not limited to, “streaming electrification”, within the EBD perimeter, EBD systems provide the benefits listed in an environmentally sustainable, green and affordable way without using any chemicals and without consuming any electric power.

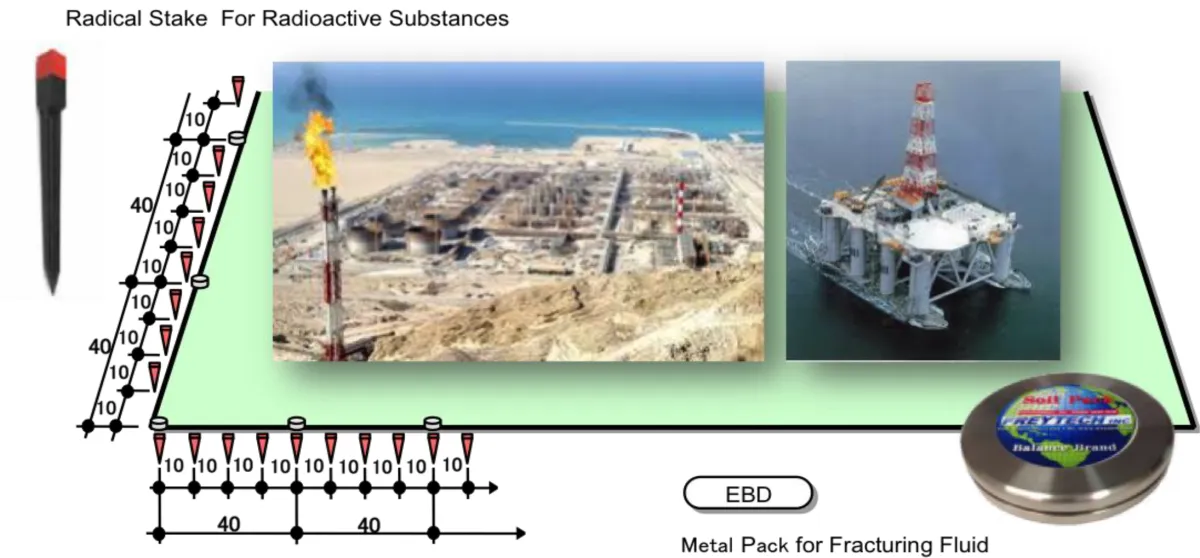

EBD Radical Stakes For Oil Well Area

EBD Radical Stakes need to be buried underground, around the perimeter of each oil well, in order to restore the balance between the positive (+) and negative (-) particle concentrations present within said perimeter. Bury one EBD Radical Stakes at 45 cm in depth in each of the 4 corners of the oil well perimeter as well as one EBD Radical Stake at each 10-meter equidistant interval in between each of 10 the 4 corners of the perimeter. The concentration balance between the air space (+) and the earth (-), will be restored and maintained usually within one year. The EBD Radical Stake units restore the balance in all matter located within the perimeter up to100 km above ground and down to 100 km below ground. That is to say, the concentration balance of the areas where the crude oil is located 1000m ~ 5000m below ground, will be sufficiently recovered. EBD Radical Stakes also counter the effects of the radioactive substances contained in the fracturing fluid and in below ground layers.

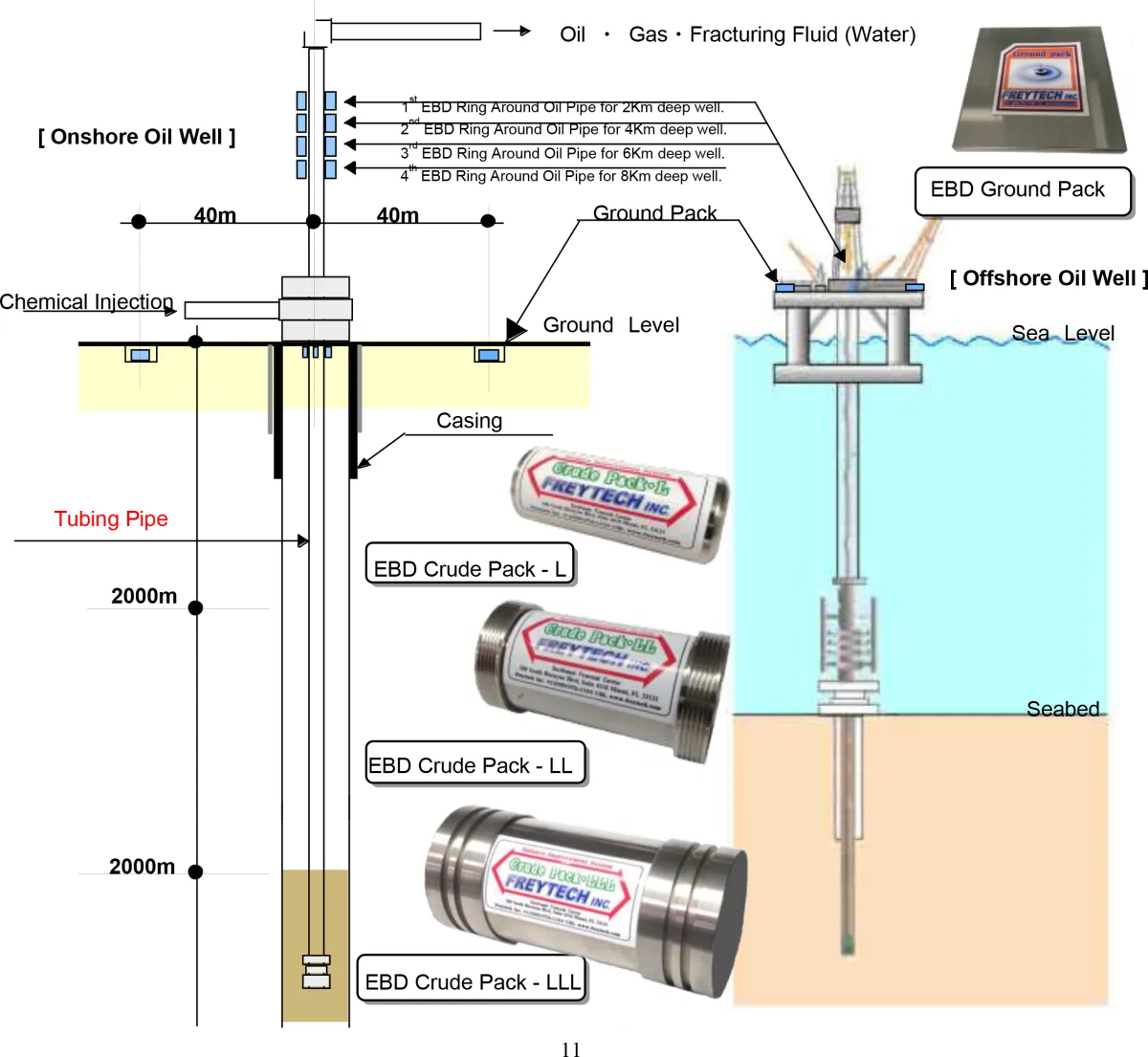

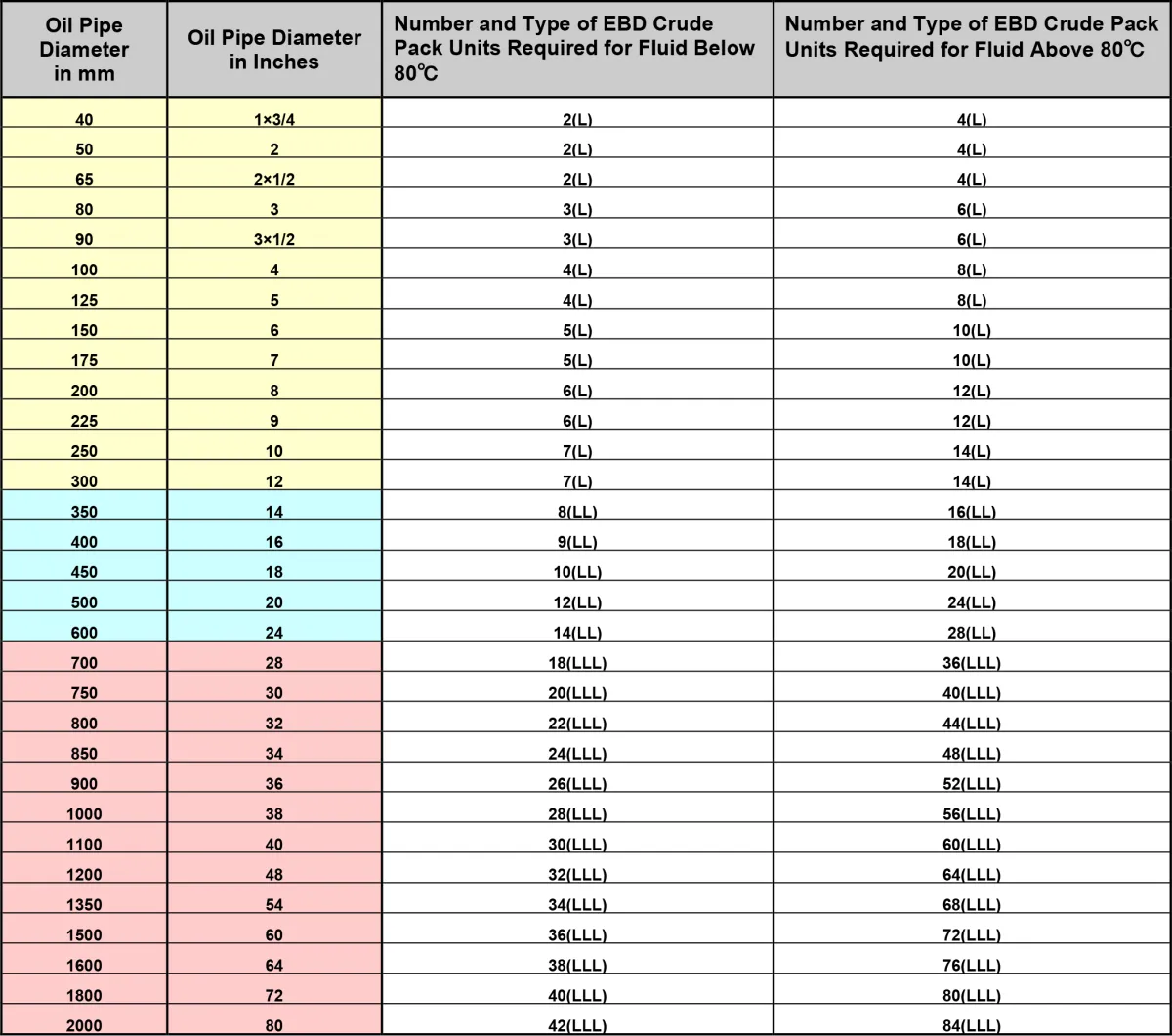

EBD Installation Diagrams Onshore & Offshore Platforms

Regarding the EBD Systems required for fluids (liquids, solids, and gases), EBD Crude Packs will also be required to achieve the required energy particle balance. They should be installed vertically (in series) in ring formation at equidistant spacing around the oil pipe. If the well is less than 2,000 m in depth, then only one set of EBD Crude Packs is required to be attached above ground to the outer surface of the vertical line of the oil well casing. The number and type of EBD Crude Packs required at each oil well, are calculated according to the diameter of the oil tube inside the casing. If the distance of the wellbore pipe is 4,000m, a double set of EBD Crude Packs need to be installed along the vertical line of the casing. If the distance is 6,000m, a triple set of EBD Crude Packs will be required and finally, if the distance is 8,000m, four sets of EBD Crude Pack systems will be required.

Quantity Needed

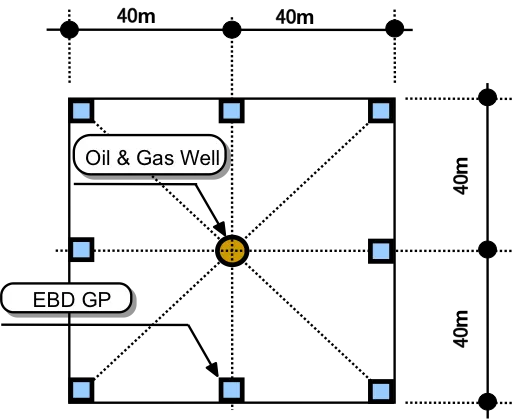

By burying the EBD Systems at 45 cm in depth around the perimeter of the oil well, all matter within said perimeter, including all the soil down to 100 km in depth will be beneficially influenced.

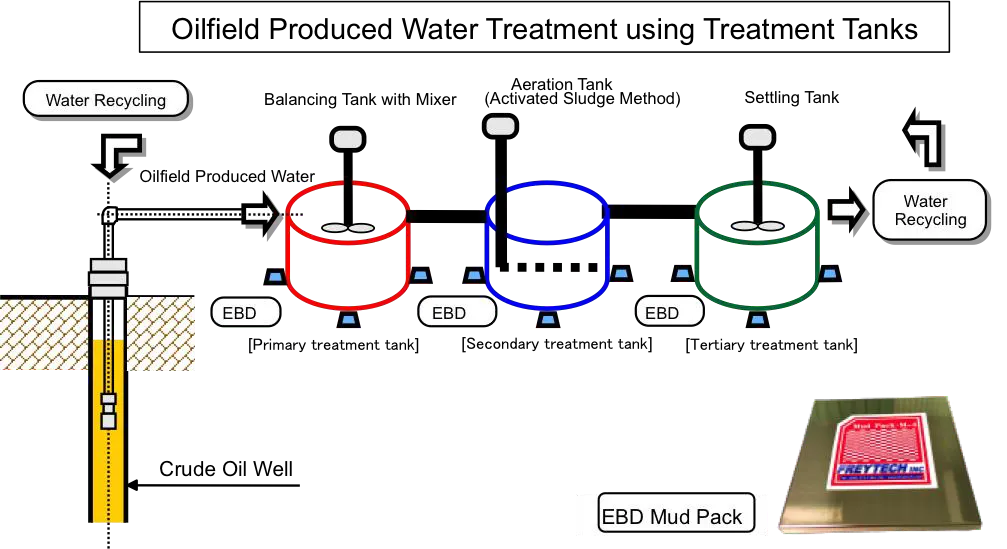

EBD SYSTEMS FOR WATER TREATMENT IN STORAGE TANKS

By burying EBD Mud Pack (Model MP3) units at 30 cm in depth, at 2 m equidistant intervals around the entire perimeter of each water treatment tank, detrimental and oxidizing Reactive Oxygen 14 Species (ROS) which exists in the waste water in each of the tanks, will be converted into a stable form of ROS. The amount of ROS will be significantly reduced and as a result, indigenous microorganisms will effectively replicate and decompose the contaminants after being enabled to consume a much heathier type of oxygen introduced naturally by the beneficial effects of EBD technology.

Each primary treatment tank should include a functioning mechanized mixer / stirring machine in order to accelerate EBD waste water treatment. If the waste water depth of the primary treatment tanks is below 3 m, mixers are not absolutely required but are still recommended. The EBD treatment target levels at this primary stage, are at 50% reduction in contaminants. By the time the EBD treated waste water from the primary treatment tanks flows into the secondary treatment tank, the BOD level will be between 500~1000mg/l.

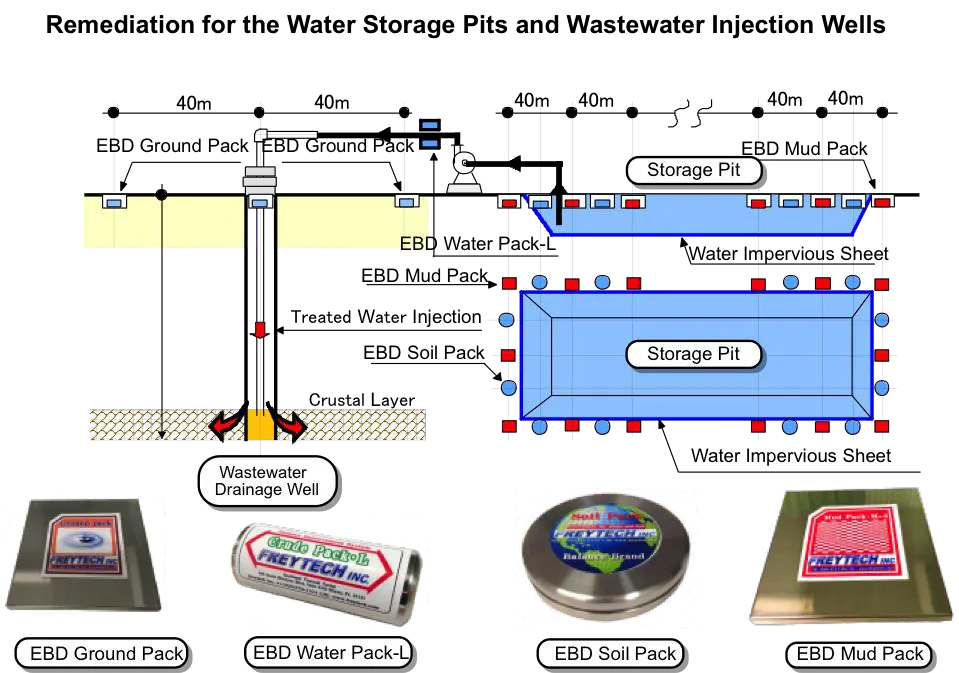

EBD SYSTEMS FOR WATER TREATMENT IN WASTEWATER PITS AND EFFLUENT WELLS

If the temporary storage pits are rectangular, EBD Mud Packs need to be buried at 30 cm in depth at each of the four corners of the tank and at 40 m equidistant intervals in between each corner. In addition, the EBD Soil Packs need to also be buried at 30 cm in depth at 20 meter equidistant intervals in between the location of each EBD Mud Pack.

In addition, EBD Ground Pack (GP) units will be required to be buried around the treated water injection pump. Eight (8) EBD Ground Pack units are required for each treated water injection pump. Each EBD Ground Pack, should be buried at 30 cm in depth, each at 40 m in distance to the 8 cardinal points where the pump is located. GP units will contribute towards the creation of a balanced state below ground, and this will enhance smooth microbial activation.

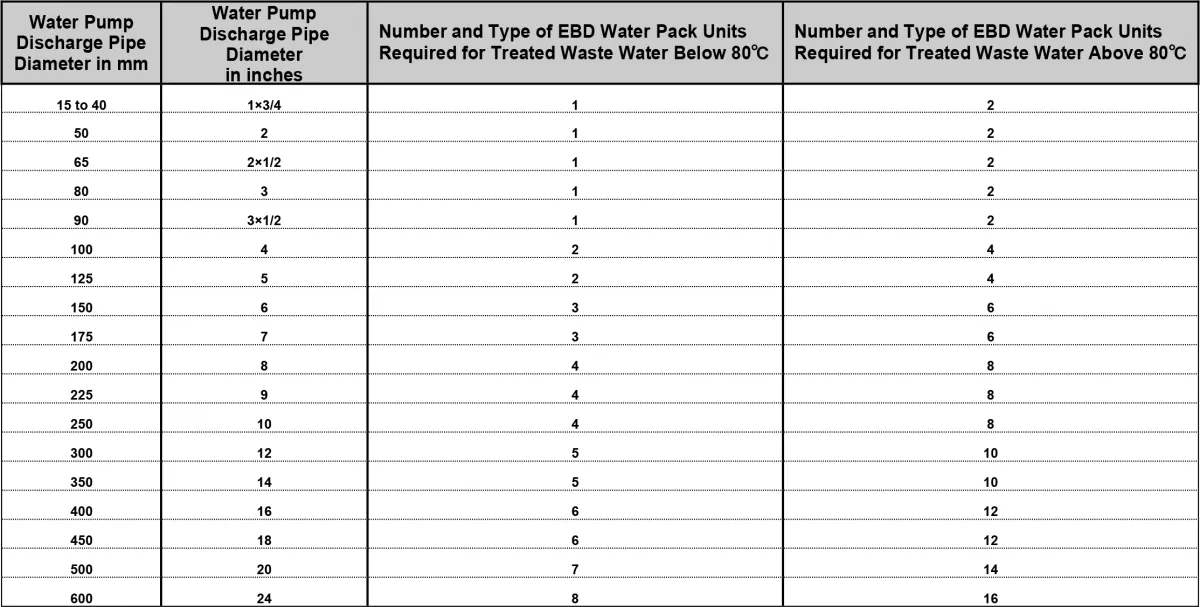

Water Packs Needed

Since waste water is continually produced and flows into the treatment tanks on an ongoing basis, it will also be necessary to install EBD Water Pack units on the outer surface of the waste water pump discharge pipe. EBD Water Packs will produce and maintain a balanced state running from the treated water storage pit to the water injection well. The number of EBD Water Pack units required will be determined according to the diameter of waste water pump’s discharge pipe diameter.

Our Technology

Once installed, Environmental Balance Device (EBD) Systems begin to attract Positive Energy Particles (PEP+) concentrations to the contaminated area resulting in the reestablishment of the necessary and critical Negative Energy Particles (NEP-) / Positive Energy Particles (PEP+) balance. Once the energy field is balanced, Reactive Oxygen Species (ROS) naturally reverts back to healthy non-oxidizing oxygen.

In a pristine, clean environment, NEP- and PEP+ levels are perfectly balanced and nature is able to self-clean through natural bioremediation processes.

Revolutionary

EBD systems incorporate revolutionary cutting-edge technology which has been developed over the course of the last 28 years.

Cost Effective

EBD Systems are exceptionally affordable and in a matter of

hours can be installed anywhere